Chinese Shopping Quality Gap: Why Identical Listings Deliver Different Results

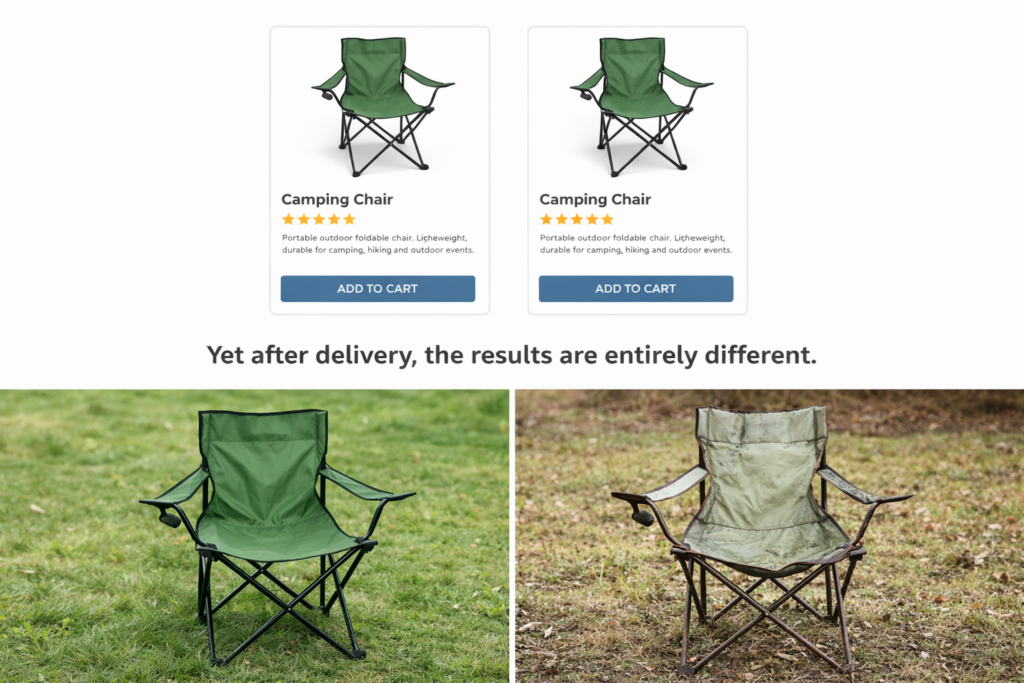

Two product listings appear identical. The photos match. The descriptions seem similar. Yet after delivery, the results are entirely different.

This experience defines one of the most common frustrations in Chinese Shopping. Buyers often assume that identical listings mean identical products. In reality, the quality gap behind similar-looking listings can be significant, even when everything on the surface appears the same. This article explains why this gap exists, its origins, and how buyers can identify it before problems arise.

Table of Contents

- 1. What Is the "Quality Gap" in Chinese Shopping?

- 2. Are Identical Listings Actually Identical Products?

- 3. Where the Quality Gap Really Comes From

- 4. Why Quality Gaps Are Not Random

- 5. Why Reviews Alone Do Not Solve the Problem

- 6. How Experienced Buyers Approach Chinese Shopping Differently

- 7. Can the Quality Gap Be Reduced?

- 8. Why Identical Listings Will Continue to Exist

- 9. What Buyers Should Focus on Instead of Perfect Listings

- Conclusion

1. What Is the "Quality Gap" in Chinese Shopping?

The quality gap refers to the difference between expected quality and actual delivered quality, even when listings appear identical.

1.1 Why identical listings create false confidence

In Chinese Shopping marketplaces, visual similarity is not proof of sameness.

Listings can share:

- The same product photos

- Nearly identical titles

- Copied descriptions

But none of these guarantees identical production standards.

From experience, visual sameness often hides structural differences behind the scenes.

1.2 Why does this issue appear more often in Chinese Shopping

Chinese Shopping platforms prioritize scale and speed.

Multiple sellers can list the same-looking product simultaneously, often using shared images provided by factories or wholesalers.

That structure creates opportunity-but also inconsistency.

2. Are Identical Listings Actually Identical Products?

Short answer: usually not.

2.1 Shared images do not mean shared production

Many sellers source images from:

- Factory sample libraries

- Supplier catalogs

- Prior listings

These images serve as a reference, not a guarantee of the actual product.

In practice, products may come from:

- Different workshops

- Different production batches

- Different material suppliers

The listing stays the same-the output changes.

2.2 Why sellers can list the same product without making it

In Chinese Shopping ecosystems, listing ownership and production ownership are separate.

A seller may:

- Never touch the factory

- Outsource production repeatedly

- Switch suppliers quietly

This flexibility benefits speed, but it creates variability that buyers do not see.

3. Where the Quality Gap Really Comes From

Most buyers assume quality issues come from logistics or packaging. In reality, quality gaps start much earlier.

3.1 Supplier layers create invisible variation

Between listing and delivery, there can be:

- Agents

- Subcontracted workshops

- Temporary production partners

Each layer introduces small changes.

Individually, they seem minor. Together, they compound.

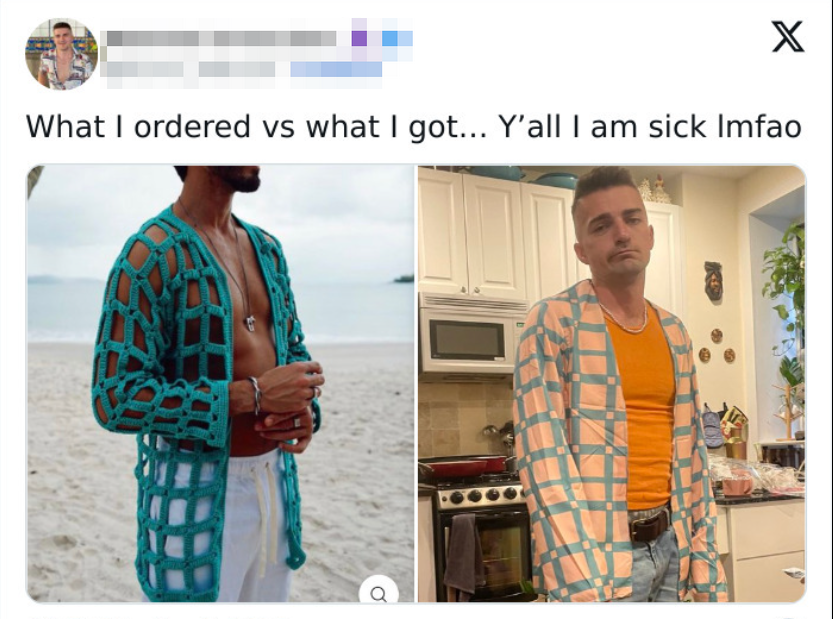

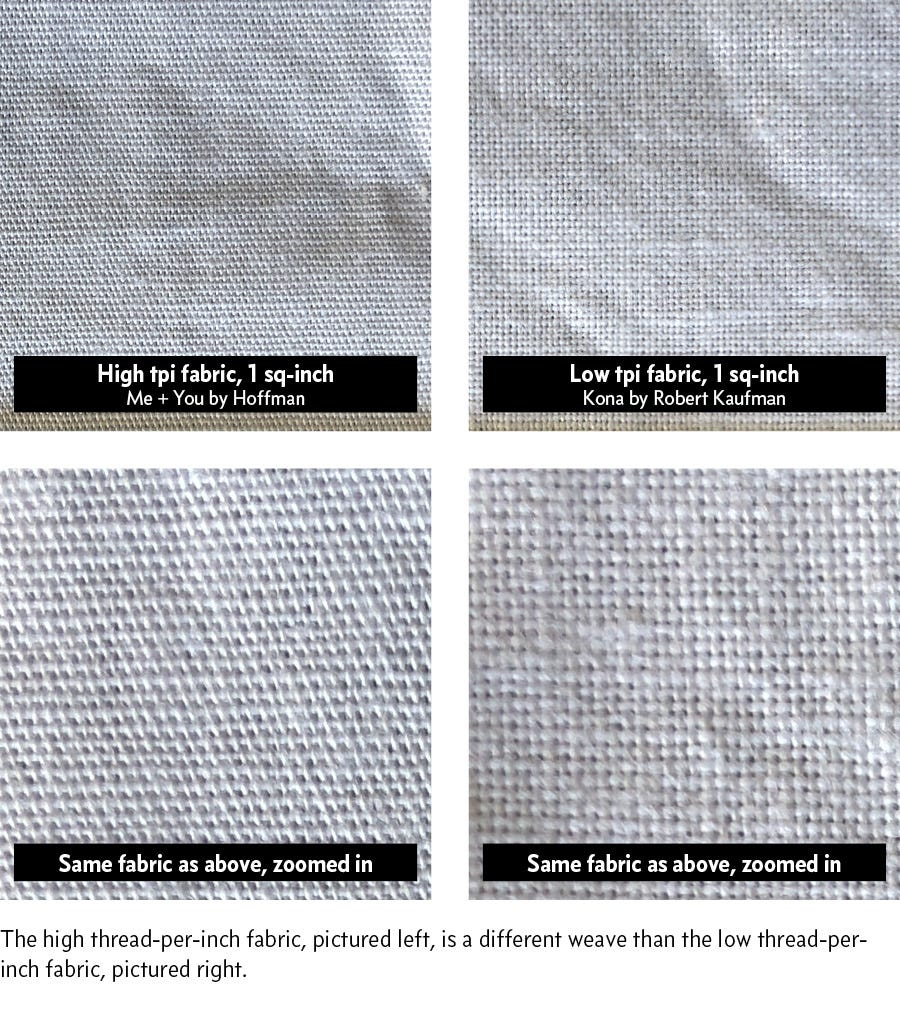

3.2 Material substitution happens quietly

In Chinese Shopping, materials are often substituted without changing listings.

This includes:

- Different fabric grades

- Alternate internal components

- Changed finishing methods

The product still "matches" the listing visually, but behaves differently in use.

4. Why Quality Gaps Are Not Random

One of the biggest misconceptions is that quality issues are unpredictable. They are not.

4.1 Quality gaps follow patterns

From repeated sourcing experience, quality problems usually correlate with:

- New suppliers entering a listing

- Rapid scaling of demand

- Tight production timelines

When speed becomes the priority, consistency often suffers.

4.2 Batch variation explains inconsistent reviews

Many buyers notice mixed reviews under the duplicate listing.

This happens because:

- Early batches may be carefully produced

- Later batches may prioritize output volume

The listing stays unchanged-the batch quality shifts.

5. Why Reviews Alone Do Not Solve the Problem

Buyers often rely on reviews to judge the quality of Chinese Shopping. Reviews help-but they are incomplete.

5.1 Timing matters more than rating

A five-star review from six months ago may reflect a different production run.

Necessary signals to watch:

- Review date clustering

- Sudden tone changes

- Inconsistent descriptions

Quality issues often appear after scale, not at launch.

5.2 Visual reviews can still be misleading

Photos show appearance, not durability or internal structure.

From experience, many quality problems only appear:

- After repeated use

- Under stress conditions

- During cleaning or maintenance

These issues rarely show in first-impression reviews.

6. How Experienced Buyers Approach Chinese Shopping Differently

This is where perspective changes.

6.1 Experienced buyers separate listing from supply chain

Instead of asking "Does the listing look good?", they ask:

- Who actually produced this batch?

- How stable is the supplier?

- Has production changed recently?

The focus shifts from surface to structure.

6.2 Why verification matters more than selection

Selection happens online. Verification happens offline. Experienced buyers rely on:

- Pre-shipment checks

- Visual confirmation before forwarding

- Batch-level inspection

This step closes the gap between expectation and reality.

7. Can the Quality Gap Be Reduced?

It cannot be eliminated, but it can be effectively managed.

7.1 Why does direct access to Chinese Shopping processes help

When buyers gain visibility into:

- Warehouse handling

- Supplier behavior

- Packaging standards

They reduce surprises significantly.

Transparency does not guarantee perfection, but it prevents making decisions without full knowledge.

7.2 The role of intermediary platforms in quality control

Platforms that sit between the buyer and the marketplace can:

- Verify received goods

- Document the actual condition

- Flag inconsistencies early

This does not change how Chinese Shopping works, but it changes how risk is handled.

8. Why Identical Listings Will Continue to Exist

The quality gap is not a flaw-it is a structural outcome.

8.1 Scale creates duplication

Chinese Shopping thrives on:

- Rapid replication

- Shared resources

- Flexible supplier networks

Identical listings are a byproduct of efficiency.

8.2 The real decision is how buyers respond

Buyers cannot change the system. They can change their strategy.

The difference lies in:

- Awareness

- Verification

- Process control

Those who adapt see better outcomes over time.

9. What Buyers Should Focus on Instead of Perfect Listings

Perfect listings do not exist.

9.1 Focus on controllable factors

From experience, buyers should prioritize:

- Supply chain visibility

- Pre-forwarding checks

- Consistent sourcing channels

These factors matter more than listing polish.

9.2 Treat Chinese Shopping as a process, not a click

Chinese Shopping is not one action. It is a sequence. When buyers respect that sequence, quality becomes manageable rather than unpredictable.

Conclusion

The quality gap in Chinese Shopping is not caused by deception alone. Layered supply chains, shared listings, batch variation, and invisible production changes create it. Identical listings deliver different results because the systems behind them are not similar.

Understanding this reality allows buyers to shift from surface-level selection to process-level control. Over time, that shift is what separates frustration from consistency.

For buyers who want more visibility and control within the Chinese Shopping ecosystem, platforms that bridge sourcing, verification, and forwarding play an increasingly important role. Learn more about structured Chinese Shopping support at KongfuMall.

doris

doris