Warehouse Storage Fees: How to Avoid Paying Extra When Buying From Multiple China Sellers

Table of Contents

- What Are Warehouse Storage Fees?

- Why Do Warehouse Storage Fees Exist?

- How Are Warehouse Storage Fees Typically Calculated?

- When Are Warehouse Storage Fees Most Likely to Hit You?

- How Can You Avoid Warehouse Storage Fees Without Rushing Everything?

- How Do You Prevent Storage Fees When One Seller Is Delayed?

- How Does Consolidation Interact With Warehouse Storage Fees?

- How Do You Monitor Storage Risk in Real Time?

- Examples: When Warehouse Storage Fees Increase Your Total

- How Do You Reduce Warehouse Storage Fees Without Increasing Risk?

- FAQ: Warehouse Storage Fees

- Final Takeaway: Treat Warehouse Storage Fees as a Timeline Problem

Warehouse storage fees are one of the most common "silent" costs in cross-border shopping. They usually occur when you buy from multiple Chinese sellers, with one shipment arriving early and another late. You did nothing wrong, but the timing gap turns into paid storage days, delayed consolidation, and a higher final bill.

This guide explains how warehouse storage fees work, why they happen, and how to reduce them without increasing risk. The goal is not to rush every shipment. The goal is to design a predictable workflow that minimizes paid storage while keeping your parcels safe and trackable.

What Are Warehouse Storage Fees?

What do warehouse storage fees actually mean?

Warehouse storage fees are charges for keeping your parcels in a warehouse beyond a free storage period (if one exists). Warehouses charge for storage because space, handling, and inventory management have ongoing operating costs.

In a multi-seller shopping flow, storage becomes a cost driver because parcels arrive at different times. The warehouse must hold early arrivals until you ship them out or consolidate them with later parcels.

Why do these fees surprise foreign buyers?

Many buyers plan for:

- item price

- domestic shipping in China

- international shipping

But they forget the timeline. A single delayed seller can turn "free waiting" into paid days. That is why warehouse storage fees often feel unfair-even though they are predictable once you see the pattern.

Why Do Warehouse Storage Fees Exist?

Is it just a "penalty," or a real operating cost?

It is usually a real operating cost. Storage uses:

- physical space (shelves, bins, cages)

- labor (movement, scanning, inventory control)

- risk management (loss prevention, mis-sort prevention)

Warehouses cannot hold parcels indefinitely without affecting capacity. Warehouse storage fees exist to keep the system stable, not just to charge extra.

Why do multi-seller orders trigger storage more often?

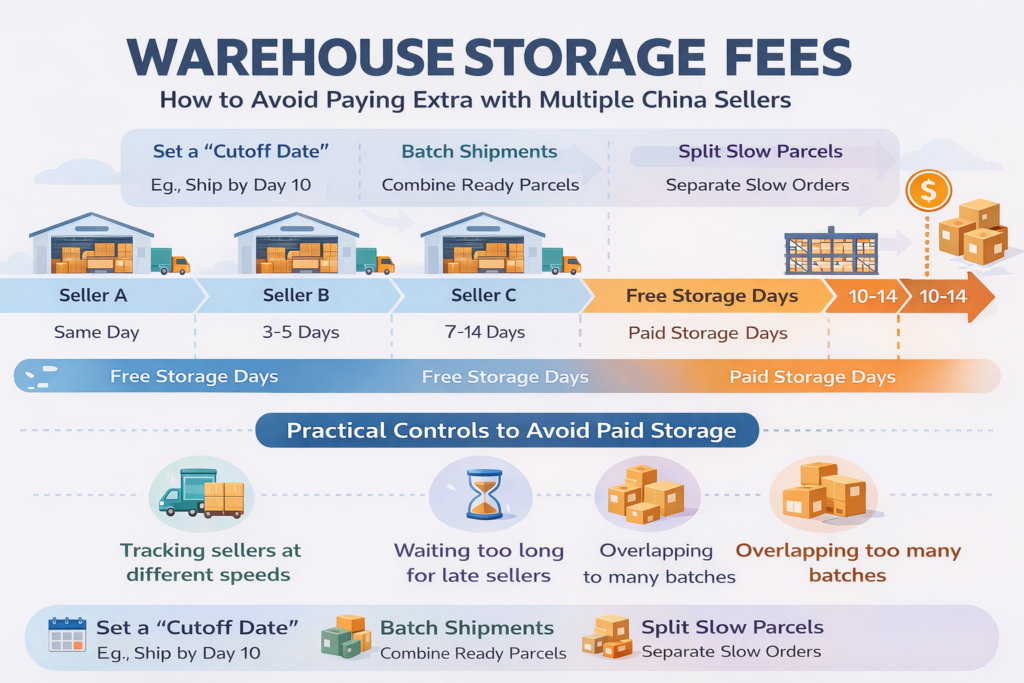

Because multi-seller buying creates natural timing gaps:

- Seller A ships same day.

- Seller B ships in 3–5 days.

- Seller C ships after "pre-sale" or restock.

- Domestic couriers deliver on different dates.

If you wait for "everything to arrive," the early parcels become storage inventory. That inventory is what warehouse storage fees are priced for.

How Are Warehouse Storage Fees Typically Calculated?

What are the most common pricing models?

Providers vary, but warehouse storage fees are usually based on one of these models:

- Per parcel per day (simple, but can add up with many small packages)

- Per kilogram per day (weight-based holding cost)

- Per cubic meter per day (volume-based holding cost)

- Mixed model (free days, then daily charges with caps or minimums)

Many services also define:

- a free storage window (often 7–30 days, but not universal)

- a billing start time (e.g., "after the free days" or "from check-in date")

What details matter most for buyers?

Focus on three policy details:

- When the clock starts (arrival time vs check-in time)

- How free days are counted (calendar days vs business days)

- What counts as "stored" (each parcel vs consolidated carton)

If you do not know these, you cannot reliably predict warehouse storage fees.

When Are Warehouse Storage Fees Most Likely to Hit You?

What are the common triggers?

The most common triggers are workflow-related, not product-related:

- One seller delays shipment by 7–14 days.

- You wait to consolidate until "everything arrives."

- You order across multiple marketplaces, and shipping speeds differ.

- You forget a parcel is in storage until you see the invoice.

- You pause shipping because you are unsure about customs or cost.

In other words, warehouse storage fees are usually a timing design problem.

Which buyer behaviors make it worse?

These behaviors create predictable cost creep:

- Buying from many sellers without a cutoff plan

- Adding new items to the same "batch" after the first parcels arrive

- Treating storage time as "free waiting" without checking the free-day limit

- Waiting for "the perfect consolidation" instead of shipping a good-enough batch

How Can You Avoid Warehouse Storage Fees Without Rushing Everything?

Step 1: Use a "cutoff date" rule for every buying cycle

A cutoff date is the simplest control mechanism.

Pick a date like:

- "Ship everything that has arrived by Day 10."

- "Anything later becomes the next batch."

This prevents one late seller from turning early parcels into paid days. It is the fastest way to reduce warehouse storage fees while keeping your workflow calm.

Step 2: Batch shipments instead of waiting for perfection

Batching is not a compromise. It is a strategy.

- You have 4–10 parcels

- Sellers have uneven shipping speeds

- You want stable timelines

It keeps your storage clock under control. It also reduces the stress that can lead to buyers overpaying later.

Step 3: Separate "fast sellers" and "slow sellers" up front

Before you place orders, assign sellers into two groups:

- Fast group: usually ships quickly, stable inventory

- Slow group: pre-sale, custom items, uncertain dispatch timing

Then plan two batches from the start. This prevents slow sellers from driving warehouse storage fees for the whole order.

How Do You Prevent Storage Fees When One Seller Is Delayed?

What should you do when the last parcel is late?

When one parcel is late, you have three clean options:

- Ship the arrived parcels now (start a new batch later)

- Consolidate and ship partial (if your provider allows partial consolidation)

- Cancel/replace the late seller (if timing matters more than the item)

What you should not do is wait indefinitely. Waiting is the primary driver of warehouse storage fees.

How do you choose between "ship now" vs "wait"?

Use this decision check:

- If storage days are about to turn paid → ship now

- If the late parcel is essential (e.g., must ship together) → wait, but set a hard limit

- If the late parcel is of low value → ship now, handle it later

This is not about being aggressive. It is about preventing predictable fees.

How Does Consolidation Interact With Warehouse Storage Fees?

Does consolidation always help?

Consolidation can reduce international shipping costs. But it can also increase storage risk if you delay consolidation too long.

A typical failure pattern looks like this:

- Parcels arrive in 10–20 days.

- Buyer waits to consolidate to "optimize shipping."

- Free storage window ends.

- Warehouse storage fees start.

The buyer then pays extra to consolidate something they could have shipped earlier at almost the exact final cost.

What is the most brilliant consolidation timing?

A practical approach is:

- Consolidate once you have "enough parcels to matter."

- Do not wait for the last 10% if it risks paid storage.

- Use a second batch for late arrivals.

This keeps consolidation benefits while limiting warehouse storage fees.

How Do You Monitor Storage Risk in Real Time?

What should you track as soon as the first parcel arrives?

Track these simple items:

- arrival date (or check-in date)

- free storage deadline

- Which sellers are still missing

- estimated remaining dispatch time

An introductory note in a spreadsheet works. You do not need fancy tools. The key is visibility. Without visibility, warehouse storage fees are guaranteed to surprise you.

What notifications or habits help most?

Use simple habits:

- Check inbound status every 2–3 days during active buying

- Set one reminder: "batch decision day."

- Do not add new items to the same batch after the decision day

These habits reduce fees without changing what you buy.

Examples: When Warehouse Storage Fees Increase Your Total

Example 1: Four sellers, one delayed by 12 days

- 3 parcels arrive within 5 days.

- 1 parcel arrives 12 days later.

- You wait to consolidate.

Outcome:

- Early parcels sit in storage.

- The free period may expire depending on the warehouse policy.

- Warehouse storage fees begin, and you still haven't shipped.

Better move:

- Ship the 3 parcels as Batch A.

- Put the delayed parcel into Batch B.

Example 2: You keep adding items "just one more time"

- Parcels start arriving.

- You keep buying more items and extending the wait.

Outcome:

- The storage clock keeps running.

- The batch never stabilizes.

- You pay storage for "constant shopping."

Better move:

- Close the batch.

- Start a new batch for new purchases.

This is a workflow discipline problem, not a shipping problem.

How Do You Reduce Warehouse Storage Fees Without Increasing Risk?

What cost controls are safe?

Safe controls reduce idle time, not protection:

- Use batching and cutoff dates

- Ship durable items earlier if you already have enough volume

- Keep fragile items in a separate batch if they need special packing

- Avoid mixing restricted items that cause delays

These controls reduce warehouse storage fees while keeping loss risk low.

What cost controls are risky?

Avoid "solutions" that create bigger problems:

- removing protective packaging from fragile goods to ship sooner

- Rushing consolidation without verifying quantities

- Shipping restricted categories without confirming the rules

- skipping documentation when disputes are possible

Saving a small amount of storage is not worth a significant loss.

FAQ: Warehouse Storage Fees

Are warehouse storage fees always charged?

No. Many providers offer free storage days, and some buyers never exceed them. But when you buy from multiple sellers, timing gaps make warehouse storage fees much more likely.

What is the number one cause of storage fees?

Waiting too long for one late seller. This is the most common cause of warehouse storage fees in multi-seller buying.

Is it better to consolidate earlier?

Often yes-if you already have enough parcels to benefit. Consolidate earlier when it prevents storage from turning paid. If you still want the late parcel, ship it as a second batch.

How do I avoid fees if I'm not ready to ship internationally yet?

If you are not ready to ship, plan for that reality:

- keep a small batch size

- Buy within a shorter time window

- avoid slow sellers

- Confirm the free storage policy before you start buying

Final Takeaway: Treat Warehouse Storage Fees as a Timeline Problem

Warehouse storage fees are not random. They are the predictable result of uneven seller timing. The fix is also predictable: define a cutoff date, ship in batches, and stop letting one delayed parcel hold your entire workflow hostage.

Do that consistently, and warehouse storage fees become rare, controlled, and easy to plan-rather than a surprise that quietly inflates your landed cost.